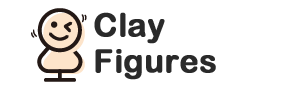

How Are Bobbleheads Made? A Step-by-Step Guide

How Are Bobbleheads Made? A Step-by-Step Guide

Many people love bobbleheads because they are whimsical and entertaining collectibles. Making a bobblehead is a complex and intriguing process involving anything from mass-produced figurines to customized designs. In this in-depth guide, we'll examine the entire bobblehead manufacturing process, from the original idea to the finished item.

Introduction to Bobbleheads

Bobbleheads, sometimes called nodders or wobblers, are figurines with an enormous head fastened to the body with a hook or spring. Because of this, even the slightest touch might cause the head to wobble. They frequently mimic fictional characters, athletes, celebrities, and even individual portraits.

Advertisements

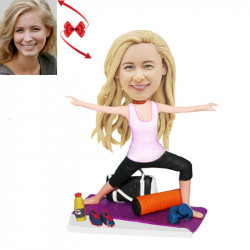

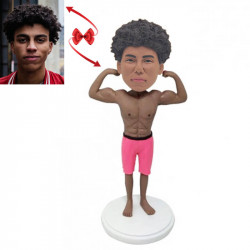

An Australian business called Bobblecustom.com sells personalized bobbleheads to consumers. Established in 2017, we finally have our own work studio after years of continuous development and study. Regardless of the specifics you wish to include, we specialize in personalized bobbleheads. We collaborate with a group of doll artists who have accumulated years of experience producing stunning handmade bobbleheads.

Step-by-Step Process of Making Bobbleheads

1. Concept and Design

The process of making a bobblehead begins with an idea. This could be a digital image, a sketch, or a photo of the person or character that has to be portrayed.

Designing the Bobblehead

- Initial Sketch: Artists produce a preliminary sketch based on the given pictures or descriptions.

- 3D Modeling: The sketch is converted into a 3D model using sophisticated software. This digital model makes it easier to make the required changes and see the finished product.

2. Sculpting the Prototype

Sculpting comes next after the design is complete. This entails building a tangible bobblehead prototype.

Materials Used

- Clay: Because clay is so pliable, it is used to create most prototypes.

- Resin: Most prototypes are made of clay because of its excellent flexibility.

Sculpting Process

- Hand Sculpting: Talented artists hand-sculpt the prototype, ensuring that every element of the design is captured.

- 3D Printing: Prototypes for intricate designs may be made using 3D printing technology.

3. Molding

Once the prototype has been approved, it is used to make molds. Molds guarantee uniformity among all bobbleheads and are necessary for bulk production.

Types of Molds

- Silicone Molds: These are frequently employed due to their adaptability and capacity to capture minute details.

- Metal Molds: Because of their longevity, they are utilized for larger production volumes.

4. Casting

The casting procedure starts as soon as the molds are prepared. A liquid substance is poured into the mold to make the bobblehead.

Materials Used for Casting

- Resin: favored due to its robustness and portability.

- Plastic: utilized for mass-produced, less expensive bobbleheads.

5. Assembly

The head and body components are cast separately before being assembled. A bobblehead's distinguishing characteristic is its bobbling head, which is fastened with a spring.

Assembly Process

- Attaching the Spring: The head can bobble because of a spring that is fastened between it and the body.

- Final Adjustments: To make sure the figurine is solid and the head bobs correctly, artists make last-minute tweaks.

6. Painting and Detailing

One of the most important processes is painting, which gives an object life. This step requires accuracy and a focus on details.

Painting Techniques

- Hand Painting: Each bobblehead is hand-painted by talented artists, guaranteeing precision and excellence.

- Airbrushing is used to apply even, smooth coatings to more significant areas.

Quality control is essential to guarantee that every bobblehead satisfies the requirements.

Quality Control Measures

- Inspection: Every bobblehead is examined for flaws or irregularities.

- Testing: The bobble's functionality is evaluated to ensure the head moves quickly.

8. Packaging and Shipping

The bobbleheads are meticulously wrapped and ready for shipping after passing quality inspection.

Packaging Process

- Protective Packaging: To guard against damage during transportation, each bobblehead is wrapped in protective cloth.

- Branding: Branding components like logos and design motifs are frequently found in packaging.

Common FAQs About Bobbleheads

How long does it take to make a custom bobblehead?

The complexity of the design and the artist's workload determines how long it takes to create a personalized bobblehead. The turnaround time from the first order to the finished product is typically 4–6 weeks. Additional time can be required for design approval and modifications for customized bobbleheads.

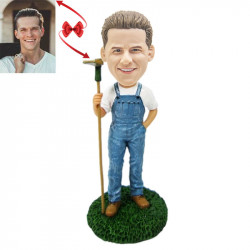

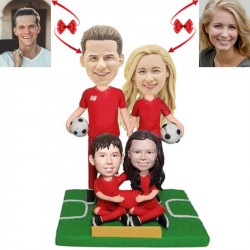

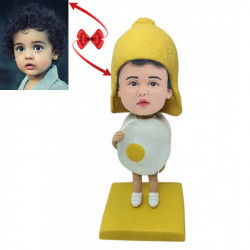

2. Can I request specific details for my custom bobblehead?

Of course! Personalized bobbleheads are our specialty at Bobblecustom.com. Customers can specify details like attire, accessories, facial expressions, and more. Our skilled doll artists painstakingly incorporate these nuances, guaranteeing that the bobblehead accurately depicts the subject.

3. What materials are used in making bobbleheads?

Usually, plastic or resin are used to create bobbleheads. Because of its resilience and capacity to preserve minute details, resin is the material of choice for personalized and superior bobbleheads. Because plastic is inexpensive and lightweight, it is frequently used to make large bobbleheads.

The Role of Bobblecustom in Bobblehead Production

Bobblecustom.com is a well-known Australian business that specializes in personalized bobbleheads. Since our founding in 2017, we have established a reliable procedure for producing high-quality bobbleheads with the help of our own work studio and a committed group of seasoned doll artists.

Why Choose Bobblecustom.com?

- Custom Designs: We provide wholly customized bobbleheads made to your preferences.

- Experienced Artists: Our talented artistic staff has years of experience creating realistic and intricate bobbleheads.

- Quality Materials: We only utilize the best materials to guarantee each bobblehead's quality and longevity.

- Customer Satisfaction: Our primary goal is to deliver superior items that go above and beyond for customers.

Conclusion

Bobblehead creation is an intriguing fusion of artistry and craftsmanship. Every stage, from the original idea to the finished result, calls for expertise, accuracy, and imagination. Knowing the bobblehead production process can help you appreciate these adorable miniatures more, whether you are searching for a personalized present or a one-of-a-kind collectible.

Table: Steps in Making Bobbleheads and Their Key Features

Step Key Features

Concept and Design preliminary drawings, 3D modeling, and thorough personalization

Sculpting the Prototype Materials such as clay, resin, 3D printing, or hand sculpting

Molding Molds made of metal or silicone that capture minute features

Casting: Using plastic or resin to create the bobblehead components

Assembly: Using a spring to secure the head ensures it bobbles properly.

Painting and Detailing Airbrushing, hand painting, accuracy, and precision

Quality Control Defect inspection and functionality testing

Packaging and Shipping Protective packaging, branded elements, preparation for safe transit

You may be confident that your personalized bobblehead will be created with the highest care and quality by using Bobblecustom.com. Through our experience and commitment, we create entertaining, customized bobbleheads that embody your thoughts.